URBAN SMH70 with double bagging

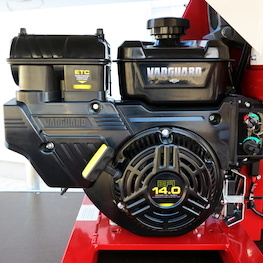

The Branch Logger URBAN SMH70 is powered by a 10 hp (optionally 14 hp or 14 hp EFI with electronic fuel injection) Briggs & Stratton VANGUARD engine. The power is transmitted from the engine by the V-belts on an oil-filled gearbox which drives the logger. The logger has road trailer with number plate bracket for easy transport to any place.

UP TO DIAMETER 80 MM

Part of the machine is: 50 pcs of raschle bags, operators manual including declaration of conformity and technical license for trailer.

- Category: URBAN SMH70

- Model series:70

- Catalogues code:SMH70 2P

- Offered from:02.03.2017

- Availability :within 2 weeks

Product variants

| Photo | Variant | |

|---|---|---|

|

URBAN SMH70 with belt conveyor 2,1 m within 2 weeks | |

|

URBAN SMH70 with belt conveyor 2,6 m within 2 weeks | |

|

URBAN SMH70 with turntable and belt conveyor 2,1 m within 2 weeks | |

|

URBAN SMH70 with turntable and belt conveyor 2,6 m within 2 weeks | |

|

URBAN SMH70 with folding conveyor 3,4 m within 2 weeks | |

|

URBAN SMH70 with turntable and folding belt conveyor 3,4 m within 2 weeks |

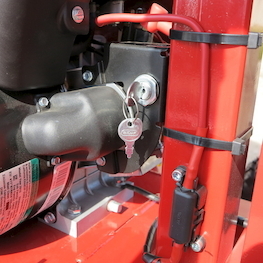

The engine

The SM70 is driven by a four stroke 10 hp Briggs & Straton VANGUARD engine (optionally 14 hp or 14 hp EFI with electronic fuel injection), with pull cord or optional electric starter. The engine´s output is transferred via V-belts to the oil filled gearbox which drives the blade rotors. The fuel tank capacity is 4 litres. Upon request, a logger can be equipped by hour meter.

The road trailer

The logger has unbraked road trailer with number plate bracket. There is a one pull-out wheel in the front of trailer and two adjustable legs on the back side of trailer. The machine is connected to a vehicle with a 50 mm diameter tow ball. The total weight of the trailer with logger is 440 kg. The maximum written weight in the registration certificate is 600 kg. The centre of gravity of the machine is slightly before the axle.

The double bagging for raschle bags

It is used raschle bags of 57 × 104 cm. The flap can be switched between filling one or the other bag. After filling the first bag, there is no need to interrupt the job due to a full bag - just flip the flap and the chips fall further into the second empty bag. During the filling of the second bag it is possible to replace the first, already full bag. Continuous insertion of the branches allows to fill bag in 20 seconds. Optimal for the operator of the machine are 2-3 persons, one of them only changing the bags. We provide 50 pcs of raschle bags free of charge with each machine.

The inlet hopper

The hopper is long enough to provide safety and is equipped with a safety shut-off frame, which by pressing down stops the engine. The inlet hopper is oriented horizontally, which greatly facilitates insertion of long branches compared to the vertical or sloping hopper. Surface treatment of the whole machine is made with powder paint.

The Overload protection

If you put too large branch in the chipping-device, V-belts slip shortly and the engine stops. This is the way how to protect the branch logger against overload. When this situation happens, it´s usually impossible to take the branch outside of the chipping-device, because knives are jammed in the branch. In this situation, make sure the engine can not start itself, put away the small round cover of V-belts and turn over with the sheave clockwise until the branch is out of the chipping device. Then, please put the cover back on the place.

The chipping device

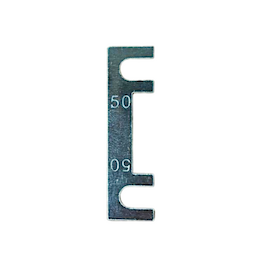

The working principle of branch loggers URBAN lies in two counter rotating shafts with knives. The rotating knives draw in the wood material into the feed hopper unassisted. The passage gap between the shafts is 70 mm. Each shaft has 3 fixed knives, made from high quality tool steel. It is possible to resharpen the knives repeatedly. After sharpening there is a pad to be put under the knives in order to keep the same gap between the knives (c. 0,1 mm). One single sharpening of knives is capable of producing from 100 to 500 solid meters of small logs, depending the level of contaminants (mud, nails, stones etc.). Each blade can be sharpened up about 4 mm, then it must be replaced with a new one.

Product inquiry

Product variants

| Photo | Variant | |

|---|---|---|

|

URBAN SMH70 with belt conveyor 2,1 m within 2 weeks | |

|

URBAN SMH70 with belt conveyor 2,6 m within 2 weeks | |

|

URBAN SMH70 with turntable and belt conveyor 2,1 m within 2 weeks | |

|

URBAN SMH70 with turntable and belt conveyor 2,6 m within 2 weeks | |

|

URBAN SMH70 with folding conveyor 3,4 m within 2 weeks | |

|

URBAN SMH70 with turntable and folding belt conveyor 3,4 m within 2 weeks |